About US

ABOUT US

Genesis International, founded in 1991, is an independent control system design and manufacturing firm specializing in HVAC and refrigeration control systems. Our design, manufacturing, and service facility is located in Arnold, MO, just south of St. Louis, MO. Our engineers have a combined experience of over 50 years in the refrigeration industry. We are dedicated to providing our customers with reliable products at a competitive price, promoting quality designs from the beginning to the end.

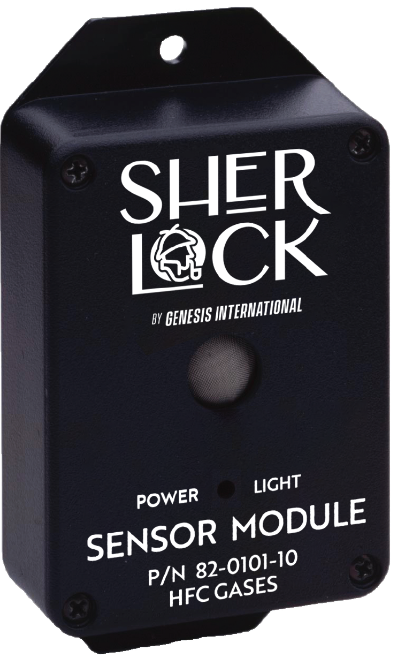

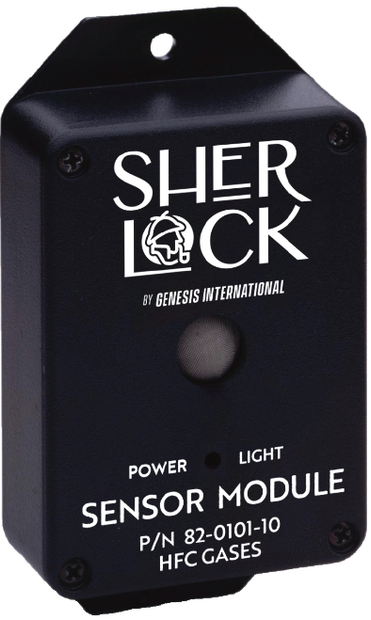

Genesis International Inc. has developed a line of refrigerant gas monitoring systems under the brand name Sherlock™. The Sherlock™ family of refrigerant gas monitoring systems are available in monitoring from 1 to 8 refrigerant sensors and are available with two and four alarm levels. The Sherlock™ monitor is also equipped with dry contacts to initiate emergency purge ventilation fans and alarm indication devices when a leak is detected and the concentrations exceed specified alarm limits. The entire line of Sherlock refrigerant leak monitoring systems is ETL/CSA approved.

Our refrigerant and ammonia gas detection sensors are available in electro-chemical, CMOs, and infrared technology types, which are designed for different gases to be used with the same monitor. We carry an electrochemical oxygen deprivation sensor, which can be used with our Sherlock monitoring system. Genesis can supply all equipment necessary for becoming ANSI/ASHRAE Standard 15-2001, Uniform Mechanical Code, and International Mechanical Code compliant.

Our Self-Contained Breathing Apparatus(SCBA) cylinders are available in 30, 45 or 60-minute models. All of our SCBAs are NISOH/MSHA rated. NFPA rated models are available. Our SCBAs are available with three enclosure options. Genesis manufactures and sells a family of refrigeration control systems for commercial and industrial refrigeration applications. Our control systems can operate most systems, from single conventional units to multiplexed parallel rack systems. These controls are ideal for retrofit applications.

The Wizard™ Multi-function Defrost Clock can control the multiple steps of an ammonia hot gas refrigeration system, multiple step electric defrost, water defrost, as well as off-time defrost cycle. The Wizard™ can monitor and alarm as to the temperature and humidity within a refrigerated space, also monitor a Sherlock™ refrigerant gas sensor and activate alarms when a leak is detected. The Wizard can make the facility mechanical code compliant by shutting down the refrigeration source valves and the electrical feeds when an alarm occurs.

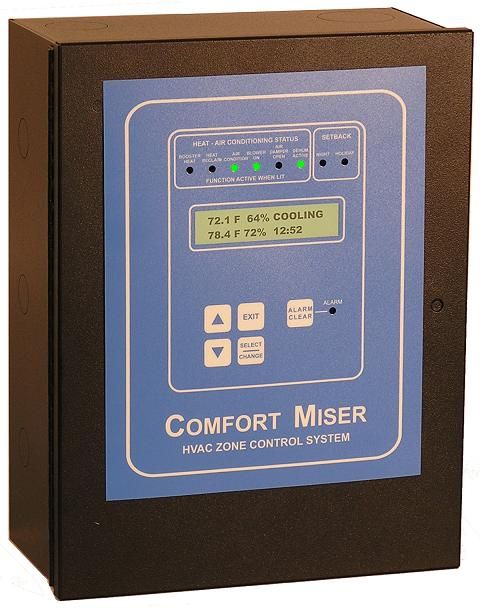

The ComfortMiser HVAC Control System can handle the entire operation of a single or dual zone air handler with multiple stages of air condition, booster heat, heat reclaim, and fan blower when available. The Comfort Miser can control air damper, auxiliary heater and the anti-sweat heaters in refrigerated display cases. It can also monitor the outside air temperature and humidity.

GenCom2 & Gencom 3000 are Genesis specific softwares facilitate remote, real-time connection to Genesis International controls on demand. They utilize internet connections to provide faster access to our control information.

Genesis can custom design, build, and support controls for commercial and industrial applications. We provide fully assembled and tested systems for easy on-site installation and startup. We utilize multi-stage noise isolation techniques to ensure highly reliable and consistent performance systems.

FREQUENTLY ASKED QUESTIONS

What is the recommended or required scheduled maintenance for the Sherlock Refrigerant controls and sensors?

There is no maintenance needed or required on our Sherlock panels. The only maintenance required is calibration which is all done on simply at the Sherlock IR or CMOS sensors for accuracy.

How do you calibrate the Sherlock IR or CMOS refrigerant sensors?

The IR sensors is very quick and simple. It’s a simple 10 second calibration by pressing the calibration push button for 10 second to calibrate the sensor back to the factory zero calibration as well to the current environment. No gas required for calibration.

What is the recommend alarm set points for leak detection for my refrigerant?

We set all our controls to a default. The Sherlock 2 series is set default at 150ppm for level 1 and 350ppm for level 2. On the Sherlock 4 series we set them default of 250ppm for level 1, 350ppm for level 2, and 450ppm for level 3. For almost all refrigerant this will keep you with in and below code requirements. Please note Ammonia and R123 need to be adjusted to a lower alarm level for your current required code. Usually for ammonia most applications require a 25ppm for level 1 and 100ppm for level 2. All the alarm levels are adjustable for PPM from 1PPM to 1000ppm alarm levels. Please always double check with you county code each county can be different.